Featured

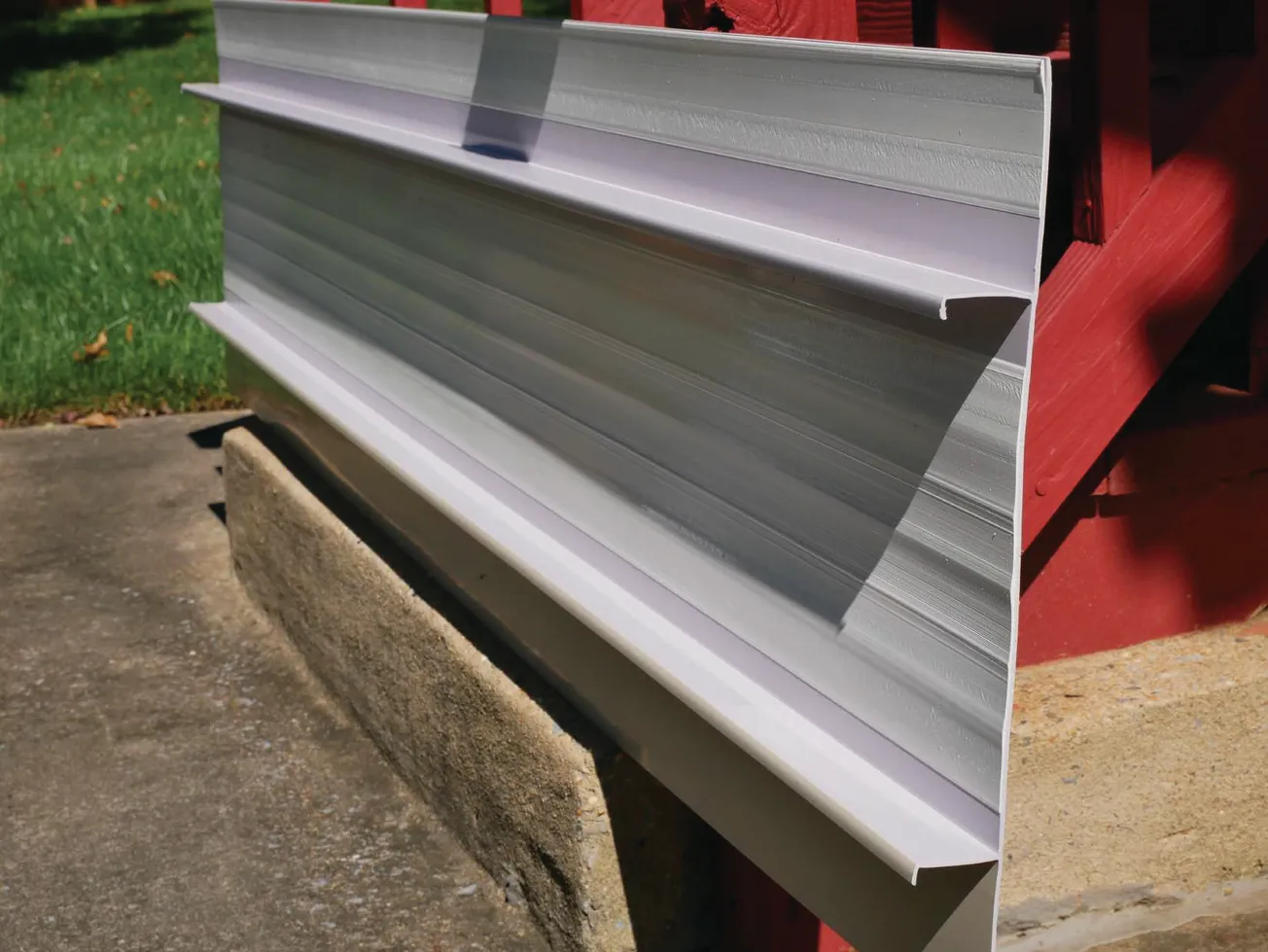

FLASHING FORWARD

LedgerShield LLC is introducing a ledger flashing system that is guaranteed to prevent catastrophic deck failures while making the job more efficient

Building Products Digest - March 2026

Building Products Digest's March 2026 Regional Woods Special Issue for lumber & building material dealers & distributors

The Merchant Magazine - March 2026

March 2026 edition of The Merchant Magazine, a monthly trade journal for the Western lumber industry

Building Products Digest - February 2026

February 2026 Spring Outdoor Living Issue of Building Products Digest, a monthly magazine for lumber & building material dealers & distributors

Merchant Magazine - February 2026

The February 2026 edition of The Merchant Magazine is the spring outdoor living issue of this monthly trade journal for the western lumber industry since 1922

COLLISION PROTECTION

Hubtex has developed Clear Aisle Assist to help prevent forklifts from bumping into racks in narrow aisles

ALUMINUM POST WRAPS

Digger Specialties has introduced Westbury aluminum post wraps, ideal for upgrading new or existing support columns or posts

REFINED MODULAR DOOR

The Modern Sliding door, part of the Marvin Modern collection, complements the existing Modern Swinging and Modern Multi-Slide doors

ANCHORING ADHESIVE

Simpson Strong-Tie has launched Strong-Bond, a fast-curing adhesive for everyday anchoring and repair of concrete, masonry and stone

QUARTERLY OUTLOOK: Q1 2026

Redbook Lumber Data's Trent Johnson provides the first installment of a new column highlighting the latest industry reports

CULTURE, METRICS & MINDSET

Kodiak Building Partners' Lance Grimm shares how to build a culture of continuous improvement for long-term success

OLSEN ON SALES: HOW DO I GROW MY SALES FORCE?

Let’s look at the pros and cons of hiring experienced vs. non-experienced sellers.

OLSEN ON SALES: SELLING IN A DOWN MARKET

The solution to selling in contracted markets? Get back to the basics.

Manufactured Stone Veneer: A Versatile Interior Design Solution

Stone has long been admired for exterior façades and landscape features—but its appeal doesn’t stop at the front door. Indoors, stone brings natural character and visual depth, transforming everyday spaces into striking design statements. Interior stone installations can be used to establish focal points, delineate adjacent spaces, and

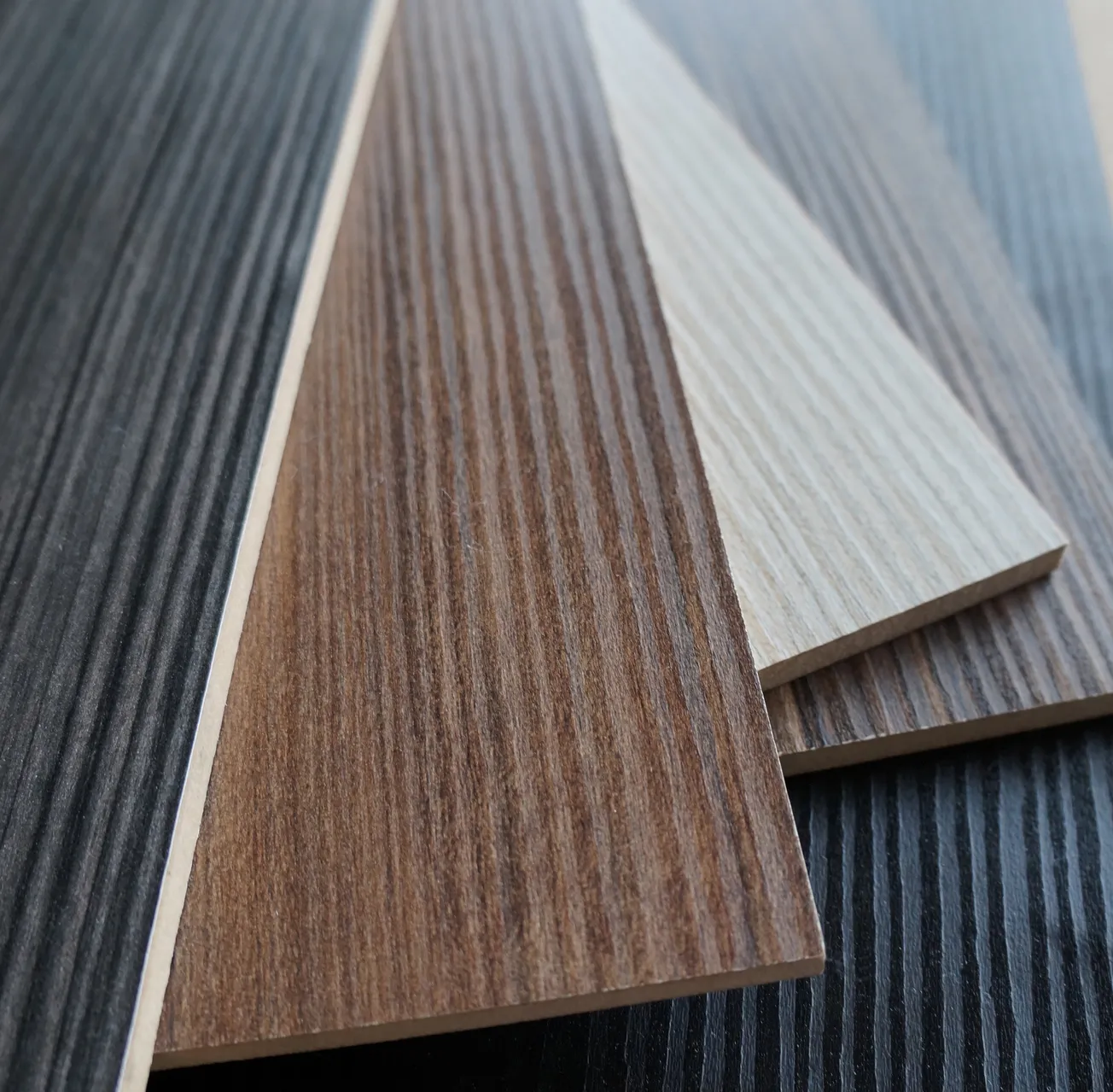

Build a Deck for All Seasons With Surestone Technology

A great deck shouldn’t be a fair-weather friend. It should be ready for spring rain, summer sun, crisp fall evenings, and the challenges of winter. That kind of year-round reliability doesn’t just happen—it comes from choosing products designed to perform in every condition. Deckorators® Voyage and Summit

HARDWOOD SUPPLIER MACDONALD & OWEN ACQUIRED

Spell Capital Partners has acquired MacDonald & Owen, West Salem, Wi., in partnership with the management team

ROSEBURG RESTARTS CONSTRUCTION ON DILLARD MDF

Roseburg has resumed construction activities at Dillard MDF

MCCOY'S READIES NEW CANEY LOCATION

Matt Daughrity has been appointed store manager of McCoy's new location under construction in New Caney, Tx.

QXO BECOMES FIRST DISTRIBUTOR MEMBER OF PEPA

QXO has become the first distributor member of the Polymeric Exterior Products Association

Editors' Picks

GANAHL EXPANDS TO SAN DIEGO WITH ACQUISITION OF PINE TREE LUMBER

Ganahl Lumber has purchased two-unit San Diego County dealer Pine Tree Lumber

WASHINGTON LUMBERYARD CLOSES AFTER 75 YEARS

Martin Lumber & Hardware, Everett, Wa., permanently closed on Oct. 11 after 75 years in business.

CAPITAL RELOCATES OREGON FACILITY

Capital Lumber has relocated to a new, upgraded facility in Donald, Or.