Table of Contents

BY BELINDA REMLEY, ARXADA

EVEN THOUGH two decades have passed since the wood treating industry voluntarily chose to move wood treatments for residential applications away from the traditional preservative called chromated copper arsenate (CCA) to newer preservatives such as micronized copper azole (MCA), there remains confusion about how to properly choose wood treated to match with its intended application. The question of whether to use Above Ground or Ground Contact treated wood has been ongoing for all of those 20+ years of new innovation.

Yet even though they may be daunted by the choice of which to buy, consumers still overwhelmingly pick beautiful, natural preserved wood for many outdoor living projects. Hundreds of thousands of preserved wood decks, fences, and other structures adorn backyards from coast to coast, giving homeowners extra space to play, relax and entertain.

“Pressure-treated lumber is chosen for its durability and its natural beauty, which is often mimicked by manufactured backyard materials,” says Jay Hilsenbeck, global product director and North American marketing director for Arxada. “But, why build with something that can only aspire to be wood, when you can build affordable, beautiful and long-lasting projects with the real thing?”

With backyard contractors choosing pressure-treated lumber for nearly 60% of their projects, it’s clear that professionals and do-it-yourselfers agree—preserved wood is the way to go. The most popular of those outdoor living projects is decks, but consumers also seek to build smaller, less involved projects such as picnic tables, benches, fences, landscape features, and raised beds for gardens.

Customers, whether they are seasoned contractors or novice DIYers, need guidance to choose the right treated wood for their projects. That purchase is the key to building outdoor projects that stand the test of time, but choosing can be daunting. How does a buyer know what kind of treated wood is appropriate for their intended application?

Selection and Use of Pressure-Treated Lumber.

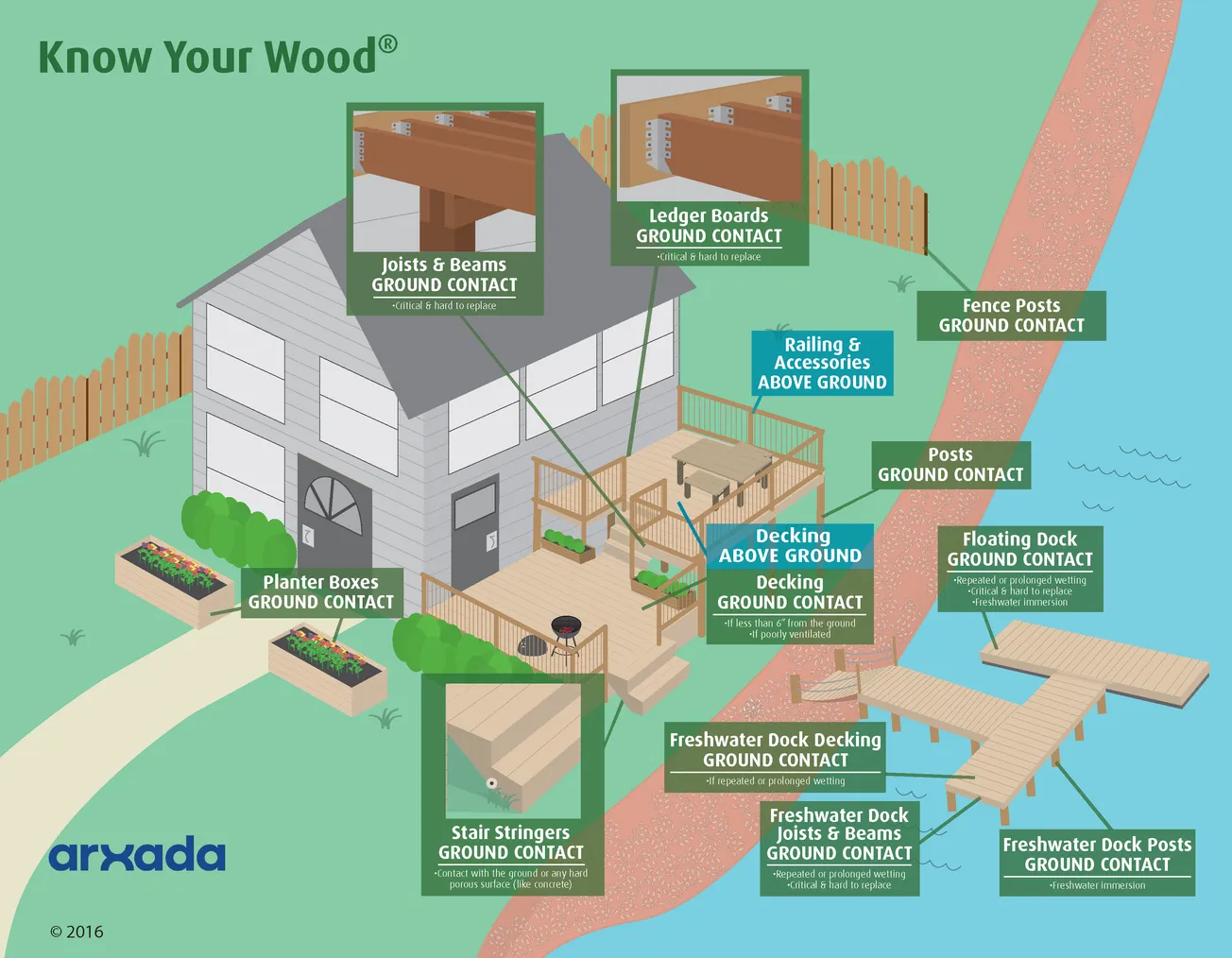

Whether building a deck’s understructure or adding the final touches such as railing or built-in seating to a project, selecting the right treated wood for each application will help it last longer. In recent years, the treated wood industry led by the American Wood Protection Association (AWPA) has worked together to defined more clear guidelines for choosing the right wood for each application. Those guidelines, indicated on end tags found on every piece of treated lumber, inform the buyer of the retention level (0.060 and 0.15 pcf) and the use category (Above Ground or Ground Contact). The required retention depends upon the severity of the exposure conditions of the wood during its service.

According to Hilsenbeck, choosing the right wood for its intended use is imperative. “Most consumers are in the market to purchase either Above Ground or Ground Contact preserved wood for their project. Ground Contact preserved wood is treated to a higher retention level than Above Ground,” he explains. “That simply means Ground Contact preserved wood has more preservative in it to offer necessary protection for more demanding end uses like raised beds, landscape retaining walls, or the structural components of a deck. While it’s possible to use Ground Contact treated wood in above ground applications, the reverse is not true. Because of this, it’s reliable advice to consider Ground Contract treated wood to be suitable as a general use product. That’s why some retailers carry only Ground Contact wood.”

Wood treated for Above Ground use is intended for parts of a project that are at least 6" above the ground, where wood dries easily, and where the wood is well-ventilated around all boards. Examples are elevated decking, railings, built-in deck benches, and fence pickets.

As Hilsenbeck explains, Ground Contact treated wood is versatile enough to be used in any application; however, it must be used in applications where the wood

• will come in contact with or be within 6" of the ground or fresh water

• is critical to the structure and/or it would be difficult to repair or replace

• is exposed to harsh conditions (even if above ground) such as prolonged contact with soil, vegetation, sprinklers, etc.

Examples include deck joists, beams, posts, stair stringers, landscaping items, and raised bed gardens.

“An easy rule of thumb is to remember if the project is in contact with the ground or fresh water or built in a manner that does not allow the wood to easily dry, Ground Contact treated wood must be used,” Hilsenbeck says.

Once the right wood is chosen, building can begin. Pressure-treated lumber can be used in construction at any time of the year. Wood is a versatile material that can be easily cut and shaped on site. And, the leftover wood from a large project can be repurposed for an additional, small project.

Got Extra Wood?

So, when your deck project is complete, what happens to the leftover wood? For the cost of just a little time, a contractor can add value to a customer’s project. Because wood is flexible and adaptable, the extra pressure-treated lumber from a larger project can be used to create an additional perk for customers, giving them the finishing touch on their outdoor oasis.

A raised bed garden, for example, is the second most popular backyard project. This can be completed quickly and easily as an added bonus for a homeowner to cultivate and enjoy for many years to come.

– Belinda Remley has been promoting the wood industry for more than 30 years. She is a marketing communications professional with Arxada, a leader in wood preservation and the preservative manufacturer behind Wolmanized Outdoor Wood (www.wolmanizedwood.com).